Markets

Coastal Protection

A Nature-Based Solutions (NBS) future with 1Print.

For the last 70 years, not much has changed in our approach to preserving and protecting the shoreline with breakwaters, seawalls, roads, and pipes—all commonly referred to as gray infrastructure and traditionally manufactured in concrete from precast, fixed molds.

But new science and new materials are offering greater resiliency and flexibility. These new approaches will better address the long-term effects of climate change and are an alternative to the traditional wave-break structures.

Key to this approach is the adoption of Nature-Based Solutions (NBS) infrastructure. This green-gray hybrid approach combines conservation and restoration of ecosystems with the selective use of “gray” human-engineered technology.

Enter 1Print and SEAHIVE®

At 1Print, our focus is to “build with nature.” We design and print Nature-Based Solutions (NBS) coastal protection systems, such as artificial reefs and seawalls, that integrate habitats for marine life. Unlike traditional fixed-cast mold-based infrastructure, our hybrid approach is based on SEAHIVE® technology—a pioneering technology that allows for hexagonal-shaped, hollow structures designed to reduce wave energy and flooding, create marine habitats, and enhance coastal resilience.

Learn more about our exclusive distribution and commercialization agreement »

SEAHIVE®: A closer look

Highly modular and adaptive, the concrete units have perforations on the sides that allow water to flow under surging or breaking waves, dissipating wave energy within the units. The perforations also form interconnected channels that provide protection for natural habitat and marine life. In fact, biocompatibility with local ecosystems is also promoted through surface roughness and material selection such as a low pH biophilic concrete mixture and non-corrosive reinforcement.

SEAHIVE® advantages:

- Wave-energy dissipation

- Protection against storm surge

- Erosion protection

- Durability

- Marine conservation

- Adaptability

- Applicability / multifunctionality

“SEAHIVE® structures slow down the waves. They minimize wave height and energy, so when the waves hit the shoreline, they’re shorter and less powerful, so we don’t have a lot of over-topping and coastal flooding. This also reduces the frequency of beach renourishment projects,”

— Diego Lirman, associate professor of marine biology and ecology at the University of Miami’s Rosenstiel School of Marine, Atmospheric, and Earth Science.

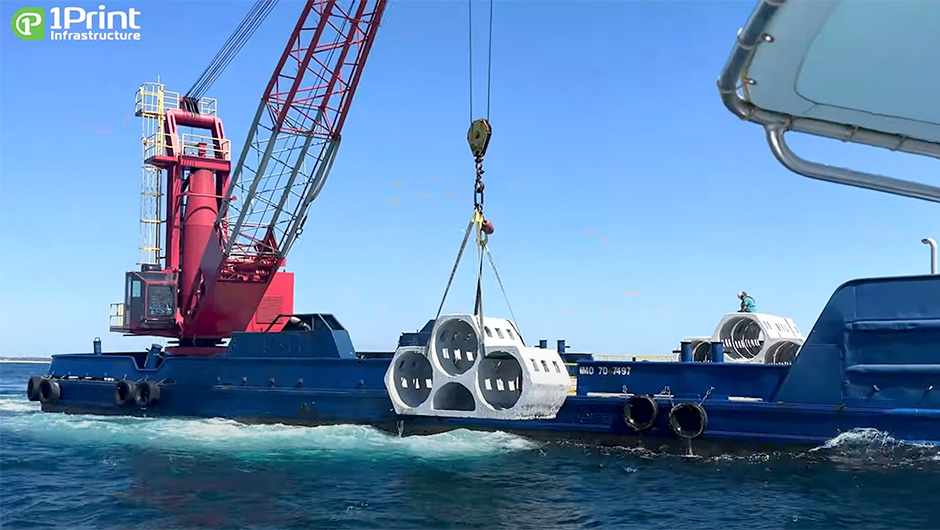

SEAHIVE® in action.

SEAHIVE® is a shoreline-protection system based on hexagonal concrete tubes. The system was developed by the University of Miami (UM) and is currently produced with innovative materials and advanced manufacturing methods, including concrete 3D printing by 1Print.

Miami North Bay Village

Miami North Bay Village, Florida, deployed a semi-cluster, hybrid coral reef with 1Print, using the SEAHIVE® technology. 3D Printing was completed in May 2023 with deployment expected in 2024. The project was sponsored by the Department of Civil and Architectural Engineering at the University of Miami.

Photo credit: University of Miami

Okaloosa

Okaloosa County in Northwest Florida deployed large 1Print manufactured SEAHIVE® clusters to protect its coastline by dissipating wave energy and restoring marine ecosystems.

Wahoo Bay

Wahoo Bay in Pompano Beach, Florida has created a hybrid, living shoreline protection system with SEAHIVE® technology. The goal is to study the marine ecosystem and combat sea level rise—an innovative approach that combines natural and human-made solutions to improve coastal resilience.